No Roman Holiday to Retool Entry at Las Vegas Resort

Digging Deeper | RenovationAugust 30, 2022

Digging Deeper | RenovationAugust 30, 2022In the ever-evolving world of Las Vegas resorts, the grand entrance at Caesars Palace had become ancient history. The area was largely unchanged since crooner Andy Williams and the “Rome Swings” revue headlined at the property’s opening in 1966.

After an eight-phase, 14-month remodeling project, Las Vegas-based The PENTA Building Group will finish a transformation early this fall of the entrance area, main casino and porte cochere to create a more expansive space with redesigned gaming areas, a new lobby bar and reworked rideshare space.

The project included raising the roof to replace the entrance’s claustrophobic 9-ft ceiling with one 22-ft high. “We had to blue sky that area, take down the old structure and add new structural steel. That phase went 24/7,” says PENTA project executive Elango “EJ” Jeyapandian.

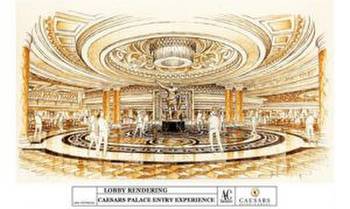

The design creates what the resort describes as “a dramatic and soaring dome and barreled ceiling over a stunning 15-ft-tall statue of Augustus Caesar.”

James Horvath, senior vice president at architect of record Bergman, Walls & Associates Ltd., says the project ties together various renovations he’s done at Caesars Palace. He adds that revamping the entrance had been discussed back when he started working for his firm 16 years ago.

“It has always been one of those things they wanted to happen, needed to happen,” says Horvath. “One of the projects conceptualized was to raise the roof on the entrance. Before, it seemed like as you walk 60 feet in any direction, it became more luxurious, more grand. It was taller and brighter. The goal of this project was to tie everything together and make it seem like it was always that way. We wanted to make it seamless.”

Crews work to replace the Caesars Palace entrance’s 9-ft ceiling with one 22 ft high.

Photo by Avisight Drone Photography

Critical Picks

Jeyapandian says a guiding principle for the entrance area and the project’s entire 28,000-sq-ft footprint was to “not impact the guest experience or their business.”

“The schedule and the logistics were the biggest challenges,” he says.

Those issues were foreseen and shaped some design choices, Horvath says. Architects worked closely with Caesars and PENTA to come up with a construction plan early in the process with a focus on smoothing out the wrinkles.

That included modifying design elements to work better with the construction phasing. One example was deciding to remodel the resort’s Galleria Bar toward the start of construction.

“In order to do that, we kept everyone out of there,” Horvath says. “Once it was done, we were able to route [customers] through this area. That came about with collaboration with the property and PENTA. We all came together and it worked out.”

The goal of avoiding customer inconvenience permeated the project, says Jeyapandian, and that included having “to pick a crane that works for everything” and mobilizing and demobilizing it with minimal disruption.

“The schedule and the logistics were the biggest challenges.”

—Elango “EJ” Jeyapandian, Project Executive, The PENTA Building Group

The resort’s main entrance was shut only twice and only briefly during the project. A Liebherr LTM-1350 crane was delivered and assembled starting late at night on Aug. 3, 2021, closing the main entrance until early afternoon the next day, all during the resort’s lighter midweek schedule.

Over the next five months, the crane conducted 12 critical picks, with the heaviest load coming in at 27,000 lb. Because of the limited space available, the crew, for instance, “had to stage air handlers in five or six pieces,” Jeyapandian says, adding that everyone on the construction team and the Caesars side “needed to know when they were going to be in the air [and] when they were dropping them in.”

The crane was disassembled during the slow week before Christmas, requiring another half-day closure of the entrance. “Typically, it takes a couple of days in a wide-open jobsite” to assemble and disassemble a crane,” Jeyapandian says. “You do it gradually.”

His team had no luxury of time or a wide-open jobsite, requiring constant synchronization among the construction crews, resort employees and an offsite staging area about a mile from Caesars.

“There was not a lot of room for handling” on site, Jeyapandian says. That required a meeting early each morning to “work through the logistics on when all of these things are going to be needed.”

The construction team then passed the information to resort executives. “Every day we created a flip book to show what was happening,” Jeyapandian says, “We were constantly communicating with Caesars.”

Focus on Safety

The efforts to safely keep the resort running during construction extended beyond the more than 2,000 linear ft of temporary wall installed to separate guests from construction during each phase.

“In our safety stand-downs, we reinforce that it’s not just our safety, it’s the safety of the guests who come on property and Caesars employees,” Jeyapandian says. “Each subcontractor conducted safety inspections throughout the entire project.”

The result has been zero time lost due to accidents on a job that had generated nearly 200,000 worker hours as of June.

Along with safety, the construction crew needed to deal with aesthetics and ensure there was as little disruption to the guest experience as possible.

Workers used their own entrance to the property and were provided “a separate path for them in the back of the house” along with maps to navigate the hidden corridors that surround the public spaces in casino resorts.

They had their own lunch space separate from tourists and resort employees, and in places where the remodeling came close to the public, there was 24-hour security and crews would “have to constantly maintain this area with cleanup,” Jeyapandian says.

One amenity the Caesars Palace remodeling project provides to the entrance area for the first time is central heating. When the property opened in the 1960s, the heat generated by incandescent lighting and electromechanical slot machines kept the area warm in winter. The move to more efficient LEDs and solid-state electronic gaming devices left the space chilly on cold days.

Along with air-conditioning, “the new air handlers now have heating capacity,” says Jeyapandian.

The project also helped modernize the gaming tables in Caesars’ main pit—the most profitable square footage at the resort. The remodeling allowed installation of high-speed data connections to monitor action at the tables, a standard feature in today’s casinos.

Scope of work includes revitalizing the entrance area, the main casino and the porte cochere to create an expansive space with redesigned gaming areas, a new lobby bar and reworked rideshare space.

Photo courtesy The PENTA Building Group

Global Supply Chain

Along with coping with the bustle of a Las Vegas resort, Jeyapandian and his team also juggled supply chain challenges that nearly caused delays in the project.

They scoured the globe to obtain stone, including emperador marble for flooring. Its finish is close to what was used in the original construction, which was no longer available. In total, the project ended up selecting stone from China, Greece, Italy and Spain and sending it to Las Vegas in 24 shipping containers.

“Once they figured out the stone, our vendor was communicating with Italy and China to get the slabs,” Jeyapandian says. “The key was to order these slabs well ahead of time and get them on the boat.”

The construction team would track the ships and plot its work around delivery of the stone, which traversed the oceans without issue until arriving at ports of entry.

“It came into Long Beach and Oakland, and on average these containers stayed in the port for four weeks,” Jeyapandian says. “If it had been a couple of more weeks, it might have affected the job.”

The team did have to improvise when there was a delay in delivery of the stone that would make up the pedestal of the Augustus Caesar statue, creating a temporary base that was in place for about a month.

Instead of the permanent two-piece base that was quarried and worked in Italy, the construction team fabricated the pedestal out of “smaller pieces until the larger piece was ready,” Jeyapandian says, adding that “it didn’t impact the job.”

The new Caesars Palace entry area wasn’t built in a day, but Jeyapandian says the project did move ahead briskly. That intensity is something that first attracted him to work in Las Vegas more than 15 years ago.

“The pace we do things here is amazing,” he says.